MOL, Rio Tinto expand joint efforts for shipping decarbonization

NewsWith Rio Tinto, MOL focuses on improving operational and technical efficiency, as well as seeking potential collaboration in alternative shipping fuels.

Mitsui O.S.K. Lines (MOL) has started operating the J-CARPS system, designed to streamline and enhance the efficiency of the car loading process for car carriers.

Japanese shipping company Mitsui O.S.K. Lines (MOL) has started operating the J-CARPS system, jointly developed with the Japan Cargo Tally Corporation.

This system is designed to streamline and enhance the efficiency of the car loading process for car carriers, a process that typically involves loading thousands of units onto a single vessel.

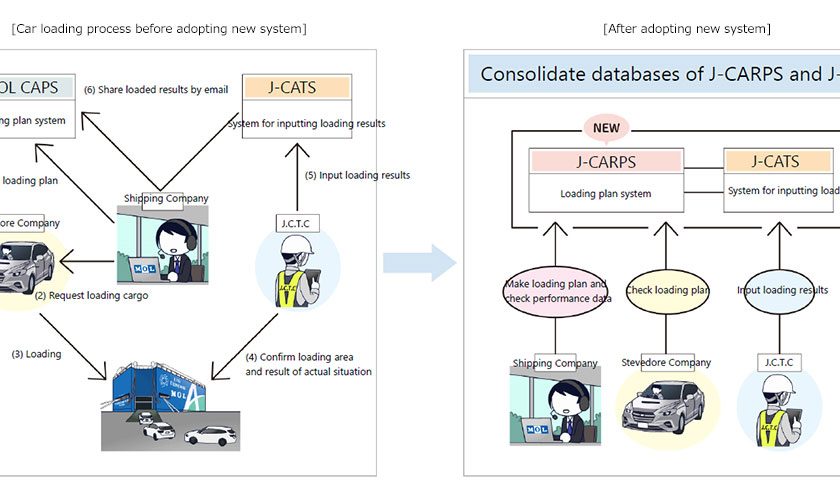

Generally, around 6,000 to 7,000 units are loaded onto a car carrier. The loading process is as follows: J.C.T.C checks (counts) where and how many cars are loaded onboard the vessel at each port in Japan, and shipping companies uses the results to prepare a cargo loading plan for the next port.

Traditionally, information about the location and quantity of cars loaded onto car carriers was managed separately by shipping companies and the J.C.T.C., with data shared via email. However, MOL recognized the potential for improved efficiency by centralizing this data into a unified system. As a result, the J-CARPS system was developed, providing a single database where all parties involved, including shipping companies, stevedore companies, and the J.C.T.C., can access and update loading plans and performance data in real-time.

One of the key features of J-CARPS is its “file attachment function” and “simple message sending function,” allowing stakeholders to communicate and collaborate seamlessly within the system. Additionally, by consolidating databases and standardizing data formats, J-CARPS eliminates discrepancies between systems and enables shipping companies to optimize loading capacity more accurately, MOL said.

In addition, shipping companies had to transcribe the diagram data of loading results received in the format of J.C.T. C’s system to its own system. Use of different systems and databases by J.C.T.C and shipping companies made it difficult to determine the exact number of units that could be added. However, unifying the databases of performance data is aimed at eliminating that problem and allow more vehicles to be loaded.

MOL expects the new system and consolidation of databases to contribute to operational efficiency in the car carrier industry, and an increase in loading capacity, given the current shortage of such vessels.

By subscribing you will have: